Generally, impregnation involves four steps: The first step to make raw graphite usable is to impregnate it with a suitable medium such as a corrosion-resistant plastic resin (phenolic or PTFE) or even carbon.ĭeep and full PTFE impregnation is the most advanced impregnation process. A micro view of resin-impregnated graphite can be seen here. Typical impregnation materials include corrosion-resistant plastic resins (phenolic or PTFE) or even carbon for the highest temperature applications (figure 3).įIGURE 3. Therefore, the first step to make raw graphite usable is to impregnate it with a suitable medium.

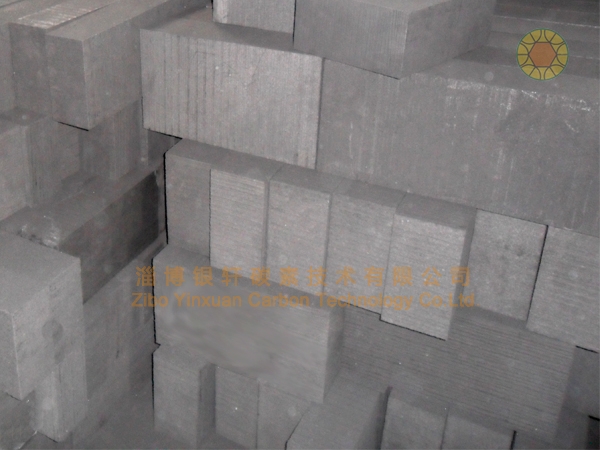

Graphite in its raw form is not impermeable, and fluids under pressure can seep through the raw graphite. Graphite grades are assigned based on their performance with respect to the severity of the fluid medium from the standpoint of corrosion, pressure and temperature. Smaller grain sizes indicate higher mechanical strength and cost more.įIGURE 2. Grain size and density are the key quality indicators of raw graphite, along with mechanical strength. PTFE gaskets are used to seal flow passages, and a special graphite cement is used to seal tube-to-tube sheet joints.

The shell-and-tube type is similar in construction to the conventional designs used in the industry, except that the tubes and plates are made of graphite. A multi-pass arrangement is possible on the tube side by suitably partitioning the headers and individual graphite blocks. The gaskets are sealed by a unique spring-loaded system that exerts a compression force on the blocks. The blocks are stacked one over the other with gaskets in between and then inserted into a steel shell. In a block- or cubic-type heat exchanger, holes are drilled in a cylindrical or cubical graphite block to form the flow passages for both the cold and hot streams. The shell-and-tube designs are best for larger sizes, high flows and fouling applications such as fertilizer manufacture. Generally, the block (figure 1) and plate types are restricted to smaller sizes, low flows and low-to-moderate heat loads.

0 kommentar(er)

0 kommentar(er)